Modified Atmosphere Tray

Modified Atmosphere Packaging (MAP), is based on a totally natural and safe process in which the atmosphere inside the package is replaced by a gas mixture suitable for the product, to maintain its shape, color and freshness.

This technology involves the use of inert gases and mixtures composed of gases already present in the air such as Nitrogen (N2), Carbon Dioxide (CO2) and Oxygen (O2) – specifically designed to stabilize and preserve the product for longer while maintaining its properties and reducing microbial growth.

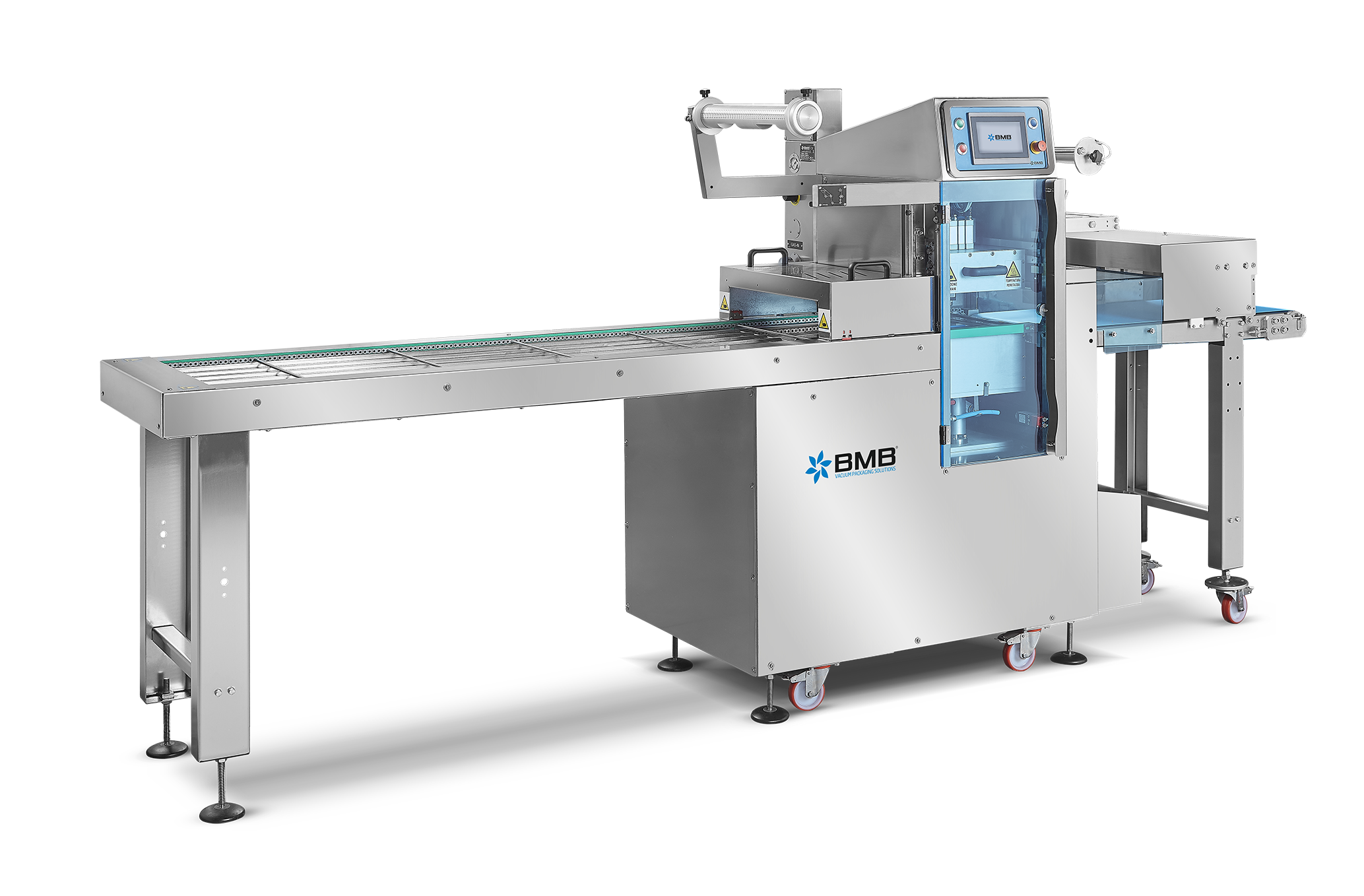

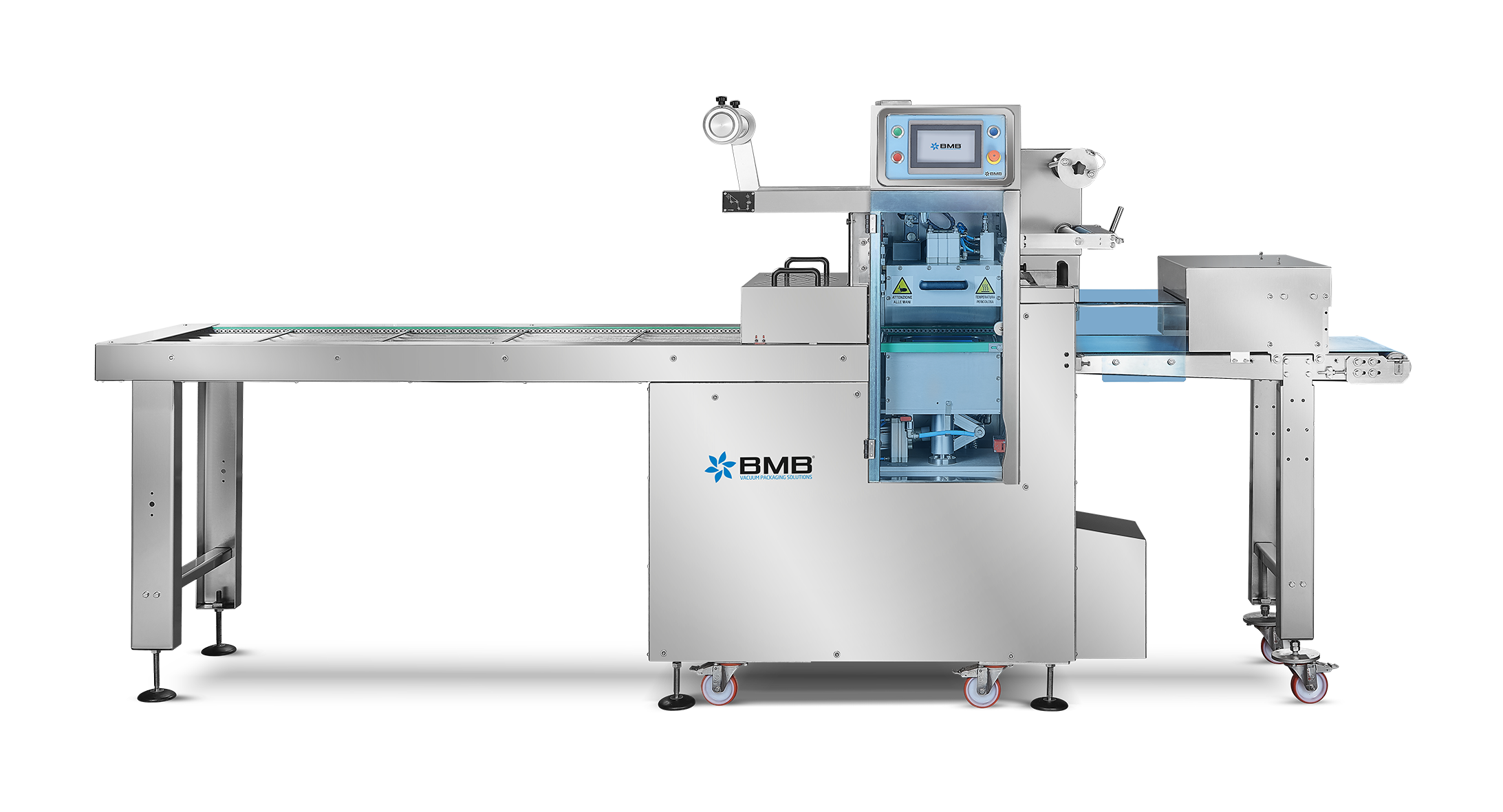

Our machines first create the vacuum by completely eliminating the air from the product, and then introduce this mixture inside the package to avoid crushing the product and the package.

The choice of gaseous mixtures that are used is closely related to the type of product to be packaged: it is necessary to evaluate the interactions that arise between the gases, the food and the packaging materials.

Benefits

Large-scale distribution looks with particular interest at this packaging system because it allows them to offer customers fresh ready-to-cook products and ready-to-eat cooked products with extended shelf life and packaged with elegant packaging that can be adapted to various marketing strategies.

There is a reduction in preservatives and additives while maintaining a long shelf life and qualitative and nutritional characteristics.

Thanks to the reduction of bacterial growth there are also greater hygienic and sanitary guarantees during the sale phase.

Finally, industrial products and consumer goods can be protected from oxidation and corrosion. In the medical technology sector, the modified atmosphere can protect the most delicate products.

Applications

It is a very versatile technology that perfectly adapts to different types of products. Generally, they are packaged in a modified atmosphere: meats, baked goods, fresh pasta, fruit and many other fresh foods.