PACKABLE PRODUCTS

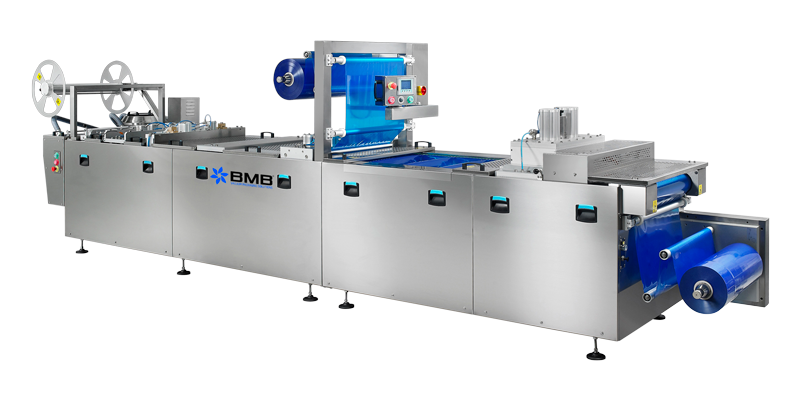

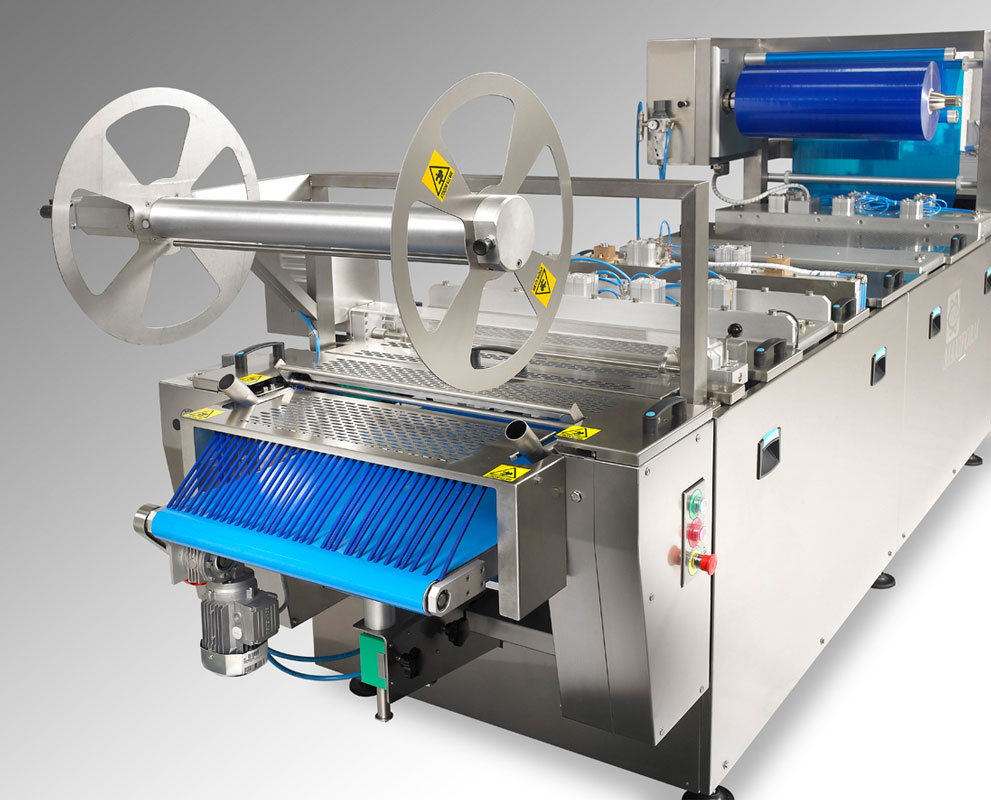

The Maxiform Thermoforming machine is completely automated, fast, reliable and extremely precise for vacuum and/or modified atmosphere packaging of any type of product with any type of film, rigid or flexible, and any other packaging material available on the market.

The greatest advantage of Maxiform is that it is fully customizable in all its features thanks to custom-made options such as the centered printing system, cut-to-shape, in-line printing and labeling and many others.

The control panel with 7” color touch-screen, multilingual, alarm log, with simplified software is easy to use and allows you to store 20 work programs. The entire production cycle is controlled by a high speed and precision microprocessor.

The Maxiform is easy to use, just as changing the film format and reel are easy. The band (width) of the lower reel film can be from 320 – 360 – 420 – 480 – 620 mm. The wheelbase and loading areas are fully customizable on customer’s request.

Remote adjustment and control interventions are possible by installing the TELESERVICE KIT with router for ETHERNET connection – Industry 4.0

The machine structure is completely in AISI 304 stainless steel and the electrical panel is in IP67 / NEMA 4 insulation class.

Suitable for any work environment, even the most aggressive, Maxiform guarantees quick and easy cleaning and maintenance operations.

Specific use: For a wide variety of food and non-food products, in thermoformed trays of different materials, sizes and formats.

What types of trays and films? Of any material and shape, including new generation ones, as long as they are compatible with each other.

Tray molds: fully customizable on customer needs.

Mould and Formats

Technical Characteristics

| Structure | Stainless steel AISI 304 |

| Control Panel | 11″ PLC Touch Screen |

| Size (LxWxH) | On request |

| Weight | On request |

| Useful chamber depth | 130/180 mm |

| Loading areas | On request |

| Maximum progress | On request, up to 1000 mm |

| Maximum diameter roll | 300 mm upper, 350 mm lower |

| Diameter of roll support | 3” (70÷76 mm) |

| Maximum film width | On request, up to 660 mm |

| Application | Sealing, Vacuum, MAP, Skin |

| Vacuum pump | 1 or 2 x 300 mc/h + booster |

| Electric supply | 400V – 3PH + N + PE |

| Pneumatic supply | 6/8 bar – dry and microfiltered air |

| Air consumption | 20-30 Nl/min |

| Speed | up to 10 cycles/min |

| Optional | Request information |