PACKABLE PRODUCTS

TYPES OF PACKAGING

The Conveyor Pro series belt vacuum packaging machines are fast and versatile machines, also designed for a long service life, which allow automatic and continuous packaging of any type of product, food and non-food, in bags for large batches size.

Automatic feeding belt makes the loading process separate from the packaging process, therefore the positioning of the products on the inlet belt can take place during the vacuum cycle, manually or by automated loading systems such as robots or product handling belts.

Thanks to the latest generation construction design and high performance, the packaging machine can reach high capacities with the best quality-price ratio on the market.

The available models differ from each other in terms of the number, length and distance between the sealing bars and the consequent size of the vacuum chamber. Hood can be equipped with three sealing bars, allowing to take full advantage of the chamber dimensions, and can be loaded from both sides.

The 7″ touch-screen color display control panel is easy to use thanks to the internally developed HMI and allows you to store up to 99 work programs. PLC manages all parameters with extreme speed and flexibility, while the Ethernet connection allows remote control of work data as well as interfacing the machine with company systems to meet the requirements of Industry 4.0.

Vacuum pump group is chosen according to the customer’s technical needs, also allowing the connection of centralized vacuum systems. Each machine guarantees precise vacuum control thanks to the absolute sensor as standard.

Machine structure is completely in AISI 304 stainless steel with an easy cleaning system including quick release of the belt, automatic water drain and electrical panel in IP67 / NEMA 4 insulation class.

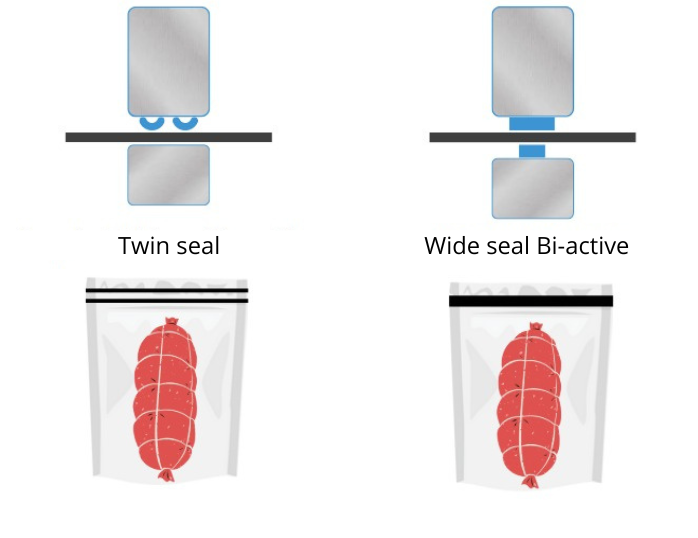

All Conveyor Pro series belt models are available with additional options such as soft-air technology for controlled re-entry, sealing bar adjustment systems to seal products of different sizes, “Twin Seal” or “Wide Seal” bi-active sealing , scrap cutting systems complete with automatic waste suction.

Specific use: For a wide variety of food and non-food products, in specific bags with different thicknesses, formats and materials including the latest generation “Eco-Friendly” ones.

What types of bags? Any (PA / PE – OPA / PP – Aluminum), for smooth or embossed vacuum, heat-shrinkable, in different thicknesses that can be easily managed by adjusting the sealing intensity standard on each model.

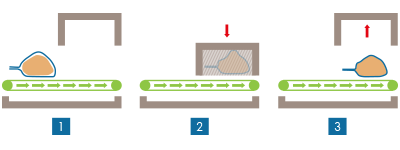

The steps of the packaging process with a vacuum chamber packaging machine.

Video

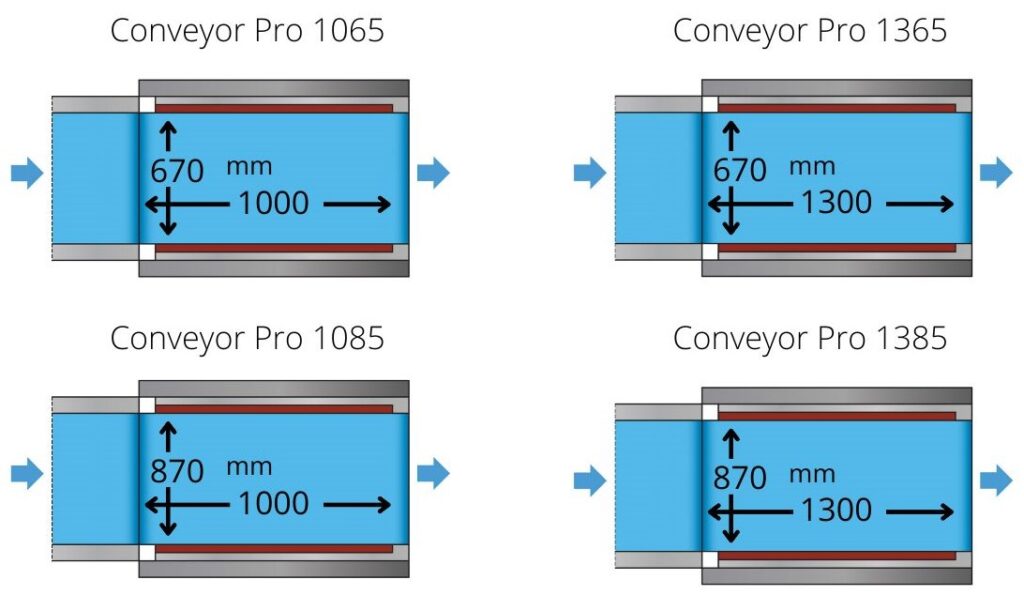

Vacuum Chamber and Sealing Bars

Vacuum Chambers

Sealing types

Technical Characteristics

Data Sheet Conveyor Pro 1065

| Structure | Stainless steel AISI 304 |

| Control Panel | 7″ PLC Touch Screen |

| Size (LxWxH) | 2741x1237x1645 mm |

| Weight | 900 kg |

| Vacuum chamber inner Size | 1110×840 mm |

| Useful lid height | 250 mm – Optional: 150-200-320 mm |

| Sealing bars | 1 or 2 x 1000 mm |

| Distance between sealing bars | 670 mm |

| Type of sealing | Monoactive or biactive. Twin seal or wide seal. |

| Belt conveyor speed | variable, up to 40 m/min |

| Vacuum pump | 1 or 2 x 300 mc/h (7,5-15 KW) + booster 500 or 1000 mc/h (5,5 KW) |

| Final Vacuum Level | 1 mbar absolute |

| Electric supply | 400V – 3PH + N + PE – 50Hz – 3KW (without pump) |

| Pneumatic supply | 6/8 bar – dry and micro-filtered air |

| Air consumption | 60 Nl/cycle |

| Speed* | 2-3 cycle/min |

| Optional | Request information |

BMB in the constant search for improvement of production, reserves the right to modify the characteristics of its products,

therefore the data and images shown are indicative and not binding. All BMB machines comply with current European

regulations according to CE, EAC and EMV.

Data Sheet Conveyor Pro 1085

| Structure | Stainless steel AISI 304 |

| Control Panel | 7″ PLC Touch Screen |

| Size (LxWxH) | 2741x1437x1645 mm |

| Weight | 1000 kg |

| Vacuum chamber inner Size | 1110×1040 mm |

| Useful lid height | 250 mm – Optional: 150-200-320 mm |

| Sealing bars | 1 or 2 x 1000 mm |

| Distance between sealing bars | 870 mm |

| Type of sealing | Monoactive or biactive. Twin seal or wide seal. |

| Belt conveyor speed | variable, up to 40 m/min |

| Vacuum pump | 1 or 2 x 300 mc/h (7,5-15 KW) + booster 500 or 1000 mc/h (5,5 KW) |

| Final Vacuum Level | 1 mbar absolute |

| Electric supply | 400V – 3PH + N + PE – 50Hz – 3KW (without pump) |

| Pneumatic supply | 6/8 bar – dry and micro-filtered air |

| Air consumption | 60 Nl/cycle |

| Speed* | 2-3 cycle/min |

| Optional | Request information |

BMB in the constant search for improvement of production, reserves the right to modify the characteristics of its products,

therefore the data and images shown are indicative and not binding. All BMB machines comply with current European

regulations according to CE, EAC and EMV.

Data Sheet Conveyor Pro 1365

| Structure | Stainless steel AISI 304 |

| Control Panel | 7″ PLC Touch Screen |

| Size (LxWxH) | 3341x1237x1645 mm |

| Weight | 1100 kg |

| Vacuum chamber inner Size | 1410×840 mm |

| Useful lid height | 250 mm – Optional: 150-200-320 mm |

| Sealing bars | 1 or 2 x 1300 mm |

| Distance between sealing bars | 670 mm |

| Type of sealing | Monoactive or biactive. Twin seal or wide seal. |

| Belt conveyor speed | variable, up to 40 m/min |

| Vacuum pump | 1 or 2 x 300 mc/h (7,5-15 KW) + booster 500 or 1000 mc/h (5,5 KW) |

| Final Vacuum Level | 1 mbar absolute |

| Electric supply | 400V – 3PH + N + PE – 50Hz – 3KW (without pump) |

| Pneumatic supply | 6/8 bar – dry and micro-filtered air |

| Air consumption | 60 Nl/cycle |

| Speed* | 2-3 cycle/min |

| Optional | Request information |

BMB in the constant search for improvement of production, reserves the right to modify the characteristics of its products,

therefore the data and images shown are indicative and not binding. All BMB machines comply with current European

regulations according to CE, EAC and EMV.

Data Sheet Conveyor Pro 1385

| Structure | Stainless steel AISI 304 |

| Control Panel | 7″ PLC Touch Screen |

| Size (LxWxH) | 3341x1437x1645 mm |

| Weight | 1200 kg |

| Vacuum chamber inner Size | 1410×1040 mm |

| Useful lid height | 250 mm – Optional: 150-200-320 mm |

| Sealing bars | 1 or 2 x 1300 mm |

| Distance between sealing bars | 870 mm |

| Type of sealing | Monoactive or biactive. Twin seal or wide seal. |

| Belt conveyor speed | variable, up to 40 m/min |

| Vacuum pump | 1 or 2 x 300 mc/h (7,5-15 KW) + booster 500 or 1000 mc/h (5,5 KW) |

| Final Vacuum Level | 1 mbar absolute |

| Electric supply | 400V – 3PH + N + PE – 50Hz – 3KW (without pump) |

| Pneumatic supply | 6/8 bar – dry and micro-filtered air |

| Air consumption | 60 Nl/cycle |

| Speed* | 2-3 cycle/min |

| Optional | Request information |

BMB in the constant search for improvement of production, reserves the right to modify the characteristics of its products,

therefore the data and images shown are indicative and not binding. All BMB machines comply with current European

regulations according to CE, EAC and EMV.