PACKABLE PRODUCTS

TYPES OF PACKAGING

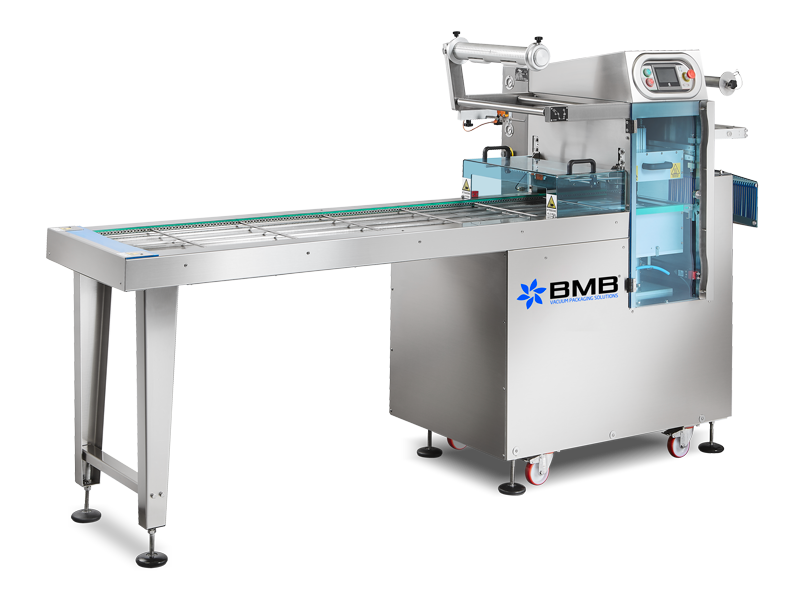

The TSC XXL thermosealer is the automatic machine with elongated surface and enlarged sealing plate, with 7 loading stations to guarantee greater production.

Reliable and safe, the TSC series machines are fully automatic in-line THERMAL SEALERS for the packaging of trays, capable of working both in normal sealing and in vacuum or in modified atmosphere. They are also able to work with SKIN effect with and without product protrusion.

TSC XXL satisfies the need to pack any product in trays, with speed and precision, in sealing only or with partial vacuum, high vacuum, modified atmosphere and skin method. The construction technology allows the installation of different formats for the packaging of different trays, with quick and easy mold changes without the use of tools. In addition, the innovative COMBI technology allows ATM and SKIN packaging without the need for format change.

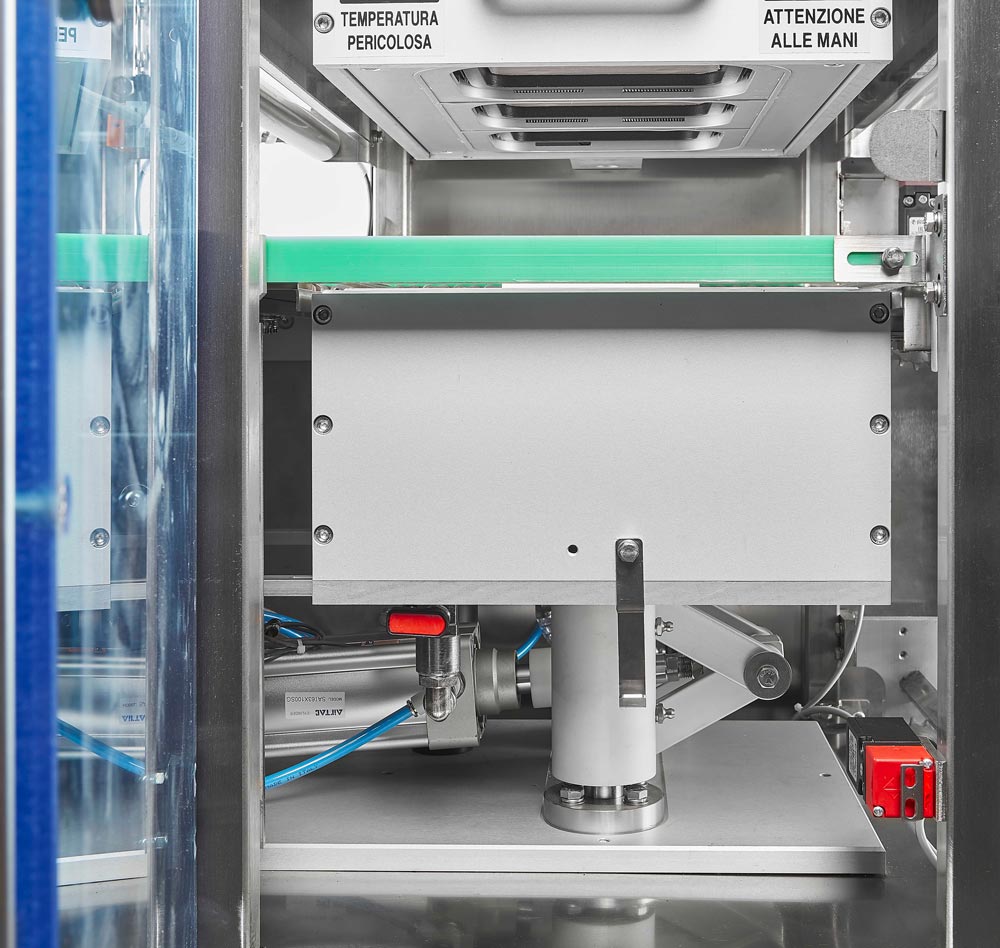

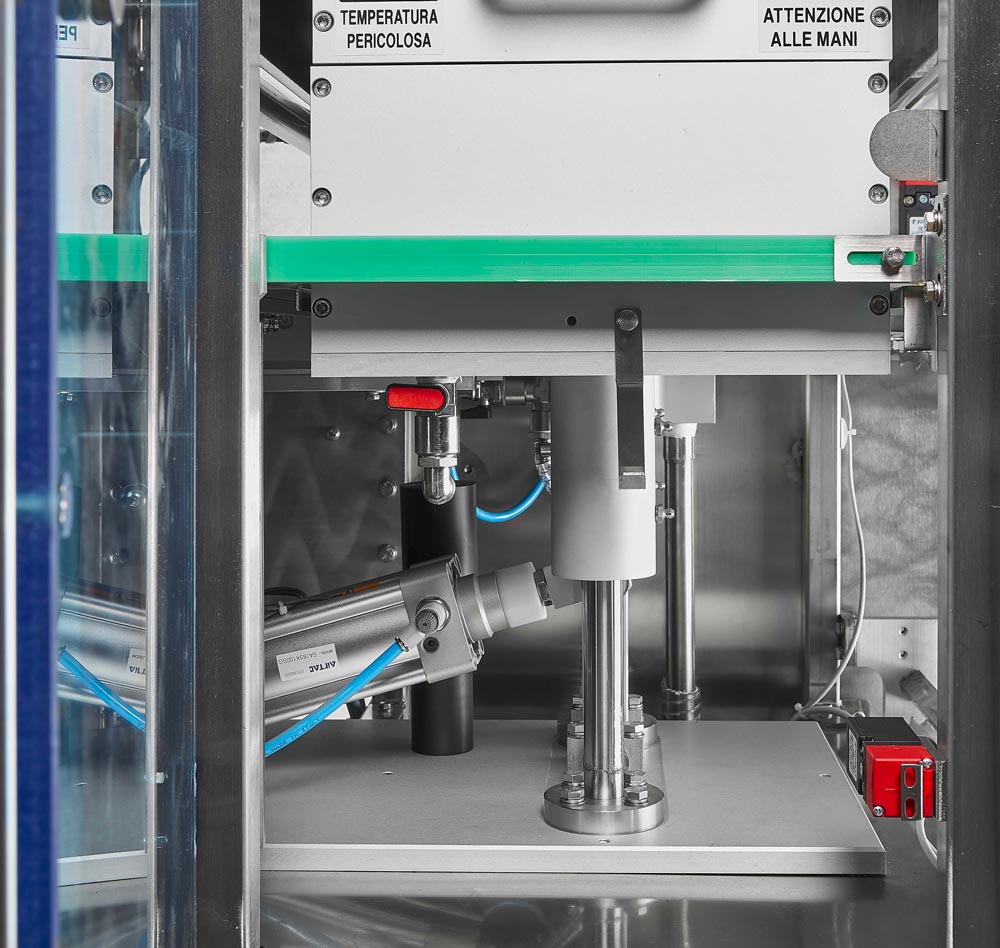

Machine is equipped with a vacuum pump included in the body of the machine and the vacuum and gas levels are controlled by an extremely accurate absolute sensor.

The sealing temperature is constantly thermoregulated with a PID system to ensure maximum packaging safety.

Practical and intuitive, the 7 “color touch-screen display facilitates the introduction of the working parameters, the management of the various functions and the display of messages and alarms.

The PLC with Ethernet connection allows remote control of the working parameters as well as interfacing the machine with company systems to meet the requirements of Industry 4.0.

The machine structure is completely in AISI 304 stainless steel and the electrical panel is in IP66 / NEMA 4 insulation class.

A complete series of dosers, destackers, lids and numerous options, allow us to meet every customer’s needs.

Video

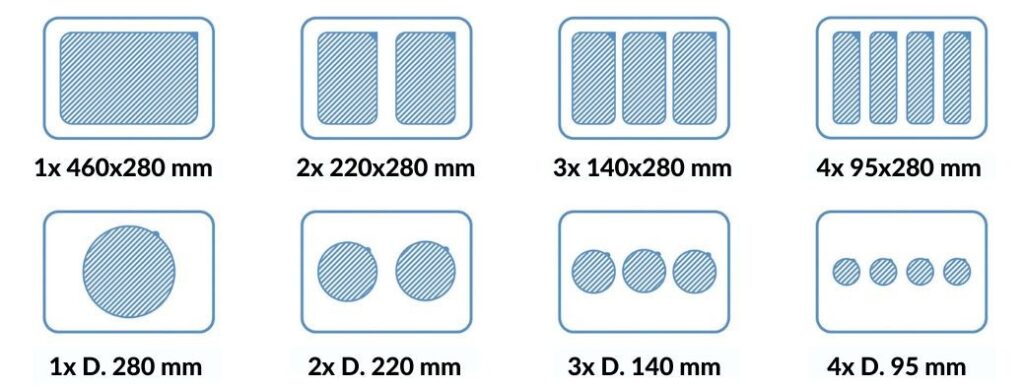

Mould and Formats

Technical characteristics

| Structure | Stainless steel AISI 304 |

| Control Panel | 7″ PLC Touch screen |

| Size (LxWxH) | 3389x1110x1760 mm |

| Weight | 550 kg |

| Loading zones | 7+1 (1750mm) |

| Sealing area | 550×290 mm |

| Tray dimensions | On request |

| Film progress | Automatic. Control by photocell or time |

| Maximum diameter roll | 300 mm |

| Diameter of roll support | 3” (70÷76 mm) |

| Maximum film width | 585 mm |

| Application | Sealing, Vacuum, MAP, Skin |

| Vacuum pump | Busch 200 mc/h – Optional: 300 mc/h |

| Final Vacuum Level | 1 mbar absolute |

| Electric supply | 400V – 3PH + N + PE – 50Hz – 4KW |

| Pneumatic supply | 6/8 bar – dry and micro-filtered air |

| Air consumption | 9-12 Nl/cycle |

| Speed * | up to 14 cycles/min – up to 10 cycles/min (MAP) – up to 6 cycles/min (SKIN) |

| Optional | Request information |

* depending on product and application

BMB in the constant search for improvement of production, reserves the right to modify the characteristics of its products,

therefore the data and images shown are indicative and not binding. All BMB machines comply with current European

regulations according to CE, EAC and EMV.